Harvest Time International and HTI Hope Center

Introduction:

Advanced Roofing took on a significant project to rehabilitate the roof at Harvest Time International (HTI) and installed a new roof on the HTI Hope Center, a new construction, in partnership with Collage Construction. This case study explores the careful planning, and teamwork that contributed to the project’s success. The efforts resulted in a durable, high performance roofing solution that supports HTI’s mission to serve the community, combining advanced techniques and strong collaboration to meet the complex demands of the facility.

HTI Mission

Harvest Time International is a faith based 501(c)(3) charitable nonprofit headquartered in Sanford, Florida, founded in 1994. It serves low income, homeless, and impoverished individuals through its Community Hope Center, offering affordable food, clothing, hygiene products, and household essentials. HTI provides free emergency aid to families in crisis, distributes gift cards, and offers Christmas toy assistance. The organization also coordinates bulk donations and supports shelters, soup kitchens, and disaster relief efforts locally and internationally, especially in Central and South America.

Phase I

The first part of the project Advanced Roofing completed was the original Harvest Time International building. This involved a flute-fill over a trapezoidal metal panel roof. The flute-fill process starts by placing insulation boards into the valleys of the metal panels, creating a uniform substrate across the entire roof surface.

Project Details

| HARVEST TIME INTERNATIONAL | HTI HOPE CENTER | ||

|---|---|---|---|

| Project dates: | June - July 2023 | April - May 2024 | |

| Roof type: | Flute-fill with TPO RhinoBond | TPO | |

| Construction manager: | Andrew Thomas | Dwayne Landry | |

| Manufacturer: | Carlisle | Carlisle | |

| Foremen: | Andrew Thomas | Dwayne Landry | |

| Project Manager: | Jeff Kluge | Sam Hussein | |

| Man days used: | 158.13 | 93.00 | |

| Squares completed: | 1028 | 296 | |

Dring the process, additional insulation boards were installed on top of the flute-fill insulation and secured with screws and plates, using six screws per board for a solid attachment.

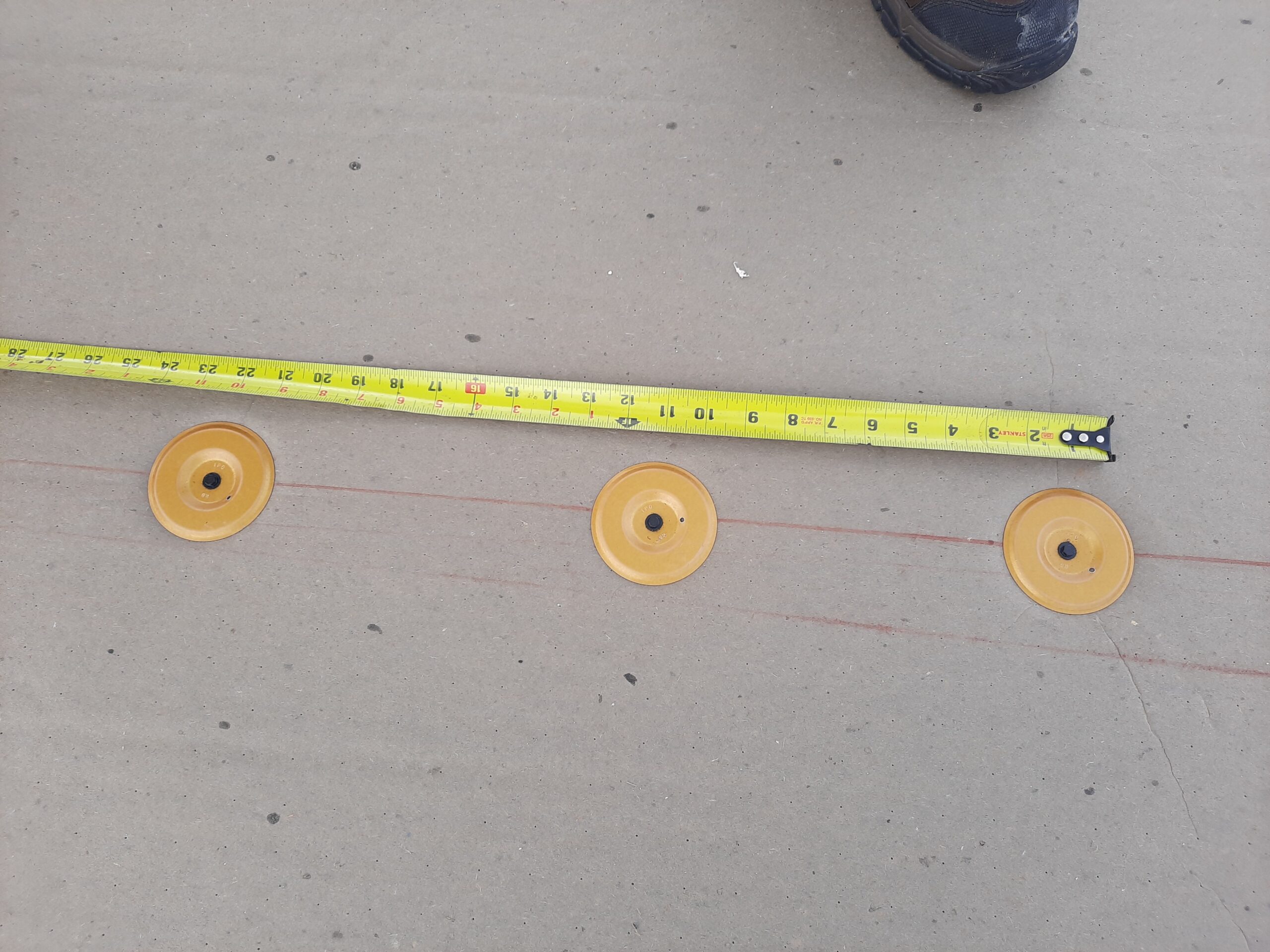

Afterward, a Carlisle 60 mil TPO single-ply membrane was installed using RhinoBond technology. This system involves screwing coated plates into the purlins, and then the membrane is rolled out and welded to the plates using induction welding machines (next slide).

- The original substrate;

- The EPS insulation used to fill the metal panels between the metal ribs;

- The flat Polyiso insulation board on top installed with metal insulation plates and fasteners;

- The gold RhinoBond plates and fasteners;

- The membrane installed over everything;

- The magnets shown are used after the induction welding machine that welded the plates to the membrane.

Because the new roof level was raised, Advanced Roofing installed new edge metal around the perimeter to ensure a smooth transition into the new gutter system. This involved adding a new wood substrate and covering it with metal for a clean finish. Detailed work followed, including vent curb flashing, flashing around HVAC units, and the installation of a new gutter. The final photo above shows the completed roof system, which provides the owner with a 20-year warranty. The project required 158 man-days, with an 8-man crew, and was completed in 20 workdays.

Phase II

Once the first roof was completed, Harvest Time rehired Advanced Roofing for their new facility across the street, called Hope Center. This new facility offers a range of essential services like:

Housing/rent assistance, Legal help, Refugee aid, Post disaster relief, Driver’s license/ID help, Nutrition classes, Senior services, Childcare assistance, Vocational training, Job placement, Career coaching, Resume Assistance, Resources for unemployed/ underemployed, Computer training, Tax assistance, Budget and GED classes, Life skills.

Before and After

The Hope Center is a newly constructed building. The General Contractor for the project was Collage, and Advanced Roofing was tasked with installing the roof. The building itself is a concrete construction, and Advanced Roofing installed metal decking as the structure for the roof system. Afterward, new insulation was installed . Advanced Roofing also worked on the newly constructed walls and managed the water flow systems. The deck has a built-in slope, directing water through various scupper openings located at different levels. The lower scupper serves as the primary drainage point, with an upper scupper functioning as an emergency overflow in case the primary gets blocked.

Walk Pads

Once the roof was completed, Advanced Roofing installed walk pads to create a clear path from the roof edge to HVAC units, mechanical equipment, and other maintenance areas. These walk pads prevent damage to the roof during routine inspections and maintenance. The entire job was completed in just 2 weeks (totaling 93 man-days with an 8-men crew).

Conclusion

This project was a significant contribution to the community. The Harvest Time now has a state of the art building that provides vital services to local residents in need. The new Hope Center will have Computer Center with printer and needed devices to write and print resumes and apply for service and Mail Center for individuals and families experiencing homelessness, so they can apply for jobs and benefits. Daily, hundreds of individuals and families visit the current facility, the active client count is over 20,000. Advanced Roofing has a long-standing history of supporting Harvest Time, regularly donating food, toys, and essential items during the holiday season and throughout the year, and we’re committed to continue to support.